Precision under pressure

How Advanced Actuators efficiently deliver optimal performance without costly physical prototyping

Hydraulic actuators keep heavy industry operations moving. Their capacity for efficiently converting fluid pressure into linear or rotary motion at high forces or speeds is crucial to industrial automation's rising prominence. Hydraulic actuators require precise engineering to ensure reliable operation with minimal maintenance in demanding or hazardous environments, whether they're controlling a valve, saw or heavy machinery.

The design process of these hydraulic systems can be intricate, particularly for specific use cases involving integrating various components with complex interactions across multiple engineering disciplines. This process often takes months, requiring extensive manual calculations and prototyping for accuracy. Firms add extra capacity to prevent failures, increasing size, cost and energy usage.

Like many sectors impacted by engineering skills shortages, actuator suppliers face increasing market demands to deliver turnkey solutions swiftly while simultaneously cutting costs and enhancing energy efficiency. It's a tall order, but Advanced Actuators Ltd. is meeting it through virtual prototyping with Simcenter™ Amesim™ and gaining significant competitive advantages.

"Rather than make physical prototypes, with Simcenter Amesim, we've proved that we can meet the customer specs before we even start to cut metal," says Chris Woodhead, director of Advanced Actuators. He also noted that this shift has resulted in a slash in design cycles, from months to weeks. "Anything that facilitates accuracy from the outset is advantageous. Speed is of the essence."

Prototyping transformed

Embracing predictive simulation and early validation has become a pivotal digital transformation for the well-established firm. Founded 55 years ago in 1969, the UK-based Advanced Actuators supplies the oil and gas, nuclear, power, water and bulk material handling sectors. "We specialize in the niche market segment that others avoid, fully integrating hydraulic and electrical controls," says Woodhead. "Our expertise lies in combining mechanical, electrical and hydraulic principles under one roof."

Advanced Actuators, supported by a network of global distributors, has established itself as a global leader in electro-hydraulic engineering. It serves clients in the Middle East, Far East, Australia and Europe. It is known for developing comprehensive, tightly integrated systems that involve numerous components and complex interactions across diverse engineering disciplines. "The ability to package everything together is a significant advantage," explains Woodhead.

The key, he says, is to understand the interactions between mechanical, electrical, and hydraulic elements and find ways to optimize them. That's where Simcenter Amesim has proven invaluable. As a mechatronic systems simulation platform – part of the Siemens Xcelerator business platform of software, hardware, and services – Simcenter Amesim allows Advanced Actuators design engineers to expedite design validation and fine-tune solutions. "Simcenter Amesim enables us to design and validate systems efficiently, reducing rework and speeding up project delivery," says Paul Hudson, Advanced Actuator's senior design engineer.

Collaborating with Maya HTT, an expert partner of Siemens Digital Industries Software, Advanced Actuators has incorporated Simcenter Amesim simulations into the early stages of their design process. “They understand the problems we’ve been giving them and how to achieve what we’re looking for,” says Woodhead.

Trimmed down to optimal size

Advanced Actuators' virtual prototyping primarily aims to optimize every aspect of the hydraulic system to arrive at a design that precisely and most efficiently meets requirements. This ensures they do not over-engineer the solution, which would inflate costs through unnecessary materials or components and can also lead to more complicated maintenance requirements and higher energy consumption. "Simulation is crucial," says Woodhead. "It is very difficult, if not impossible, to accurately assess a system's spare capacity without it."

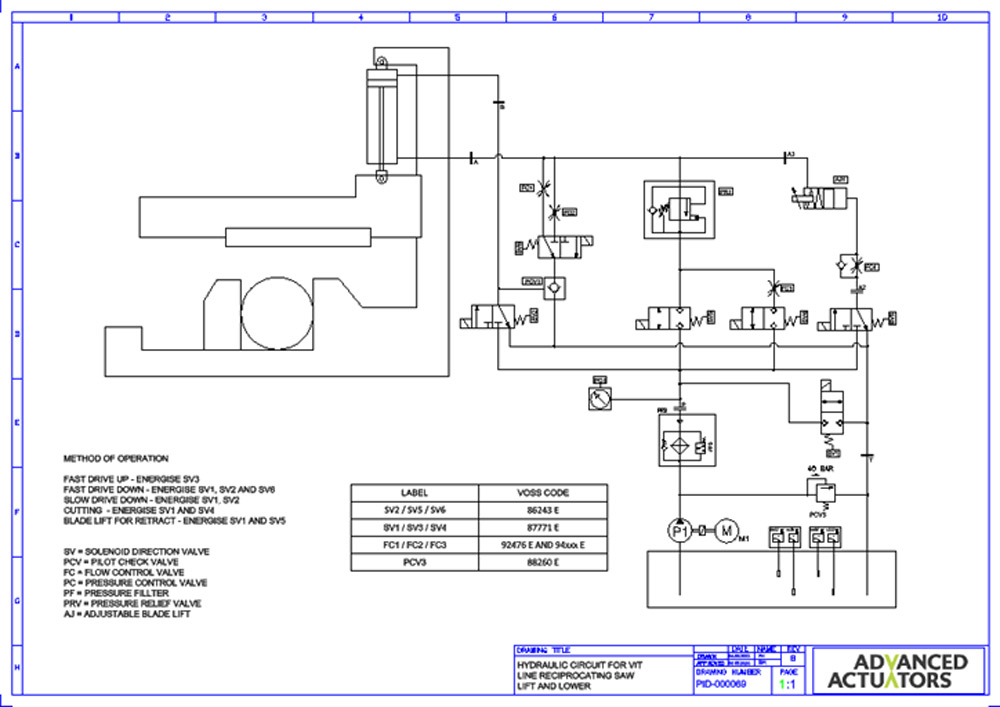

For example, Advanced Actuators worked on upgrading one client's automated, hydraulically operated linear saw, which was used for processing hazardous materials. Installed by another supplier more than 30 years ago, the system's complexity made setup challenging. Any minor adjustments by operators could halt the saw's operation, causing recurring backlogs in the preprocessing cycle that posed risks to the plant's operations.

Further complicating the project, Advanced Actuators had limited access to the equipment due to health and safety restrictions. Removing the saw to test new equipment was impossible, and physical prototyping was impractical.

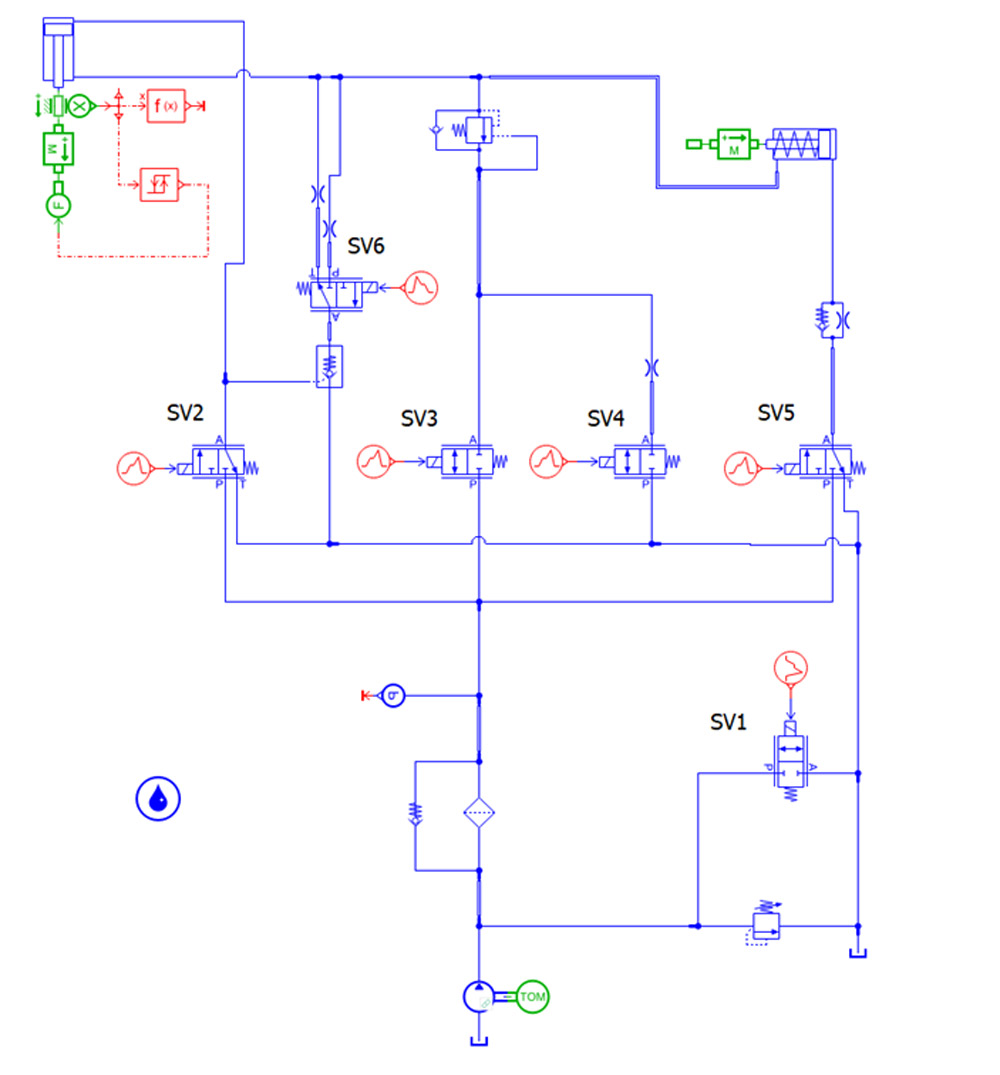

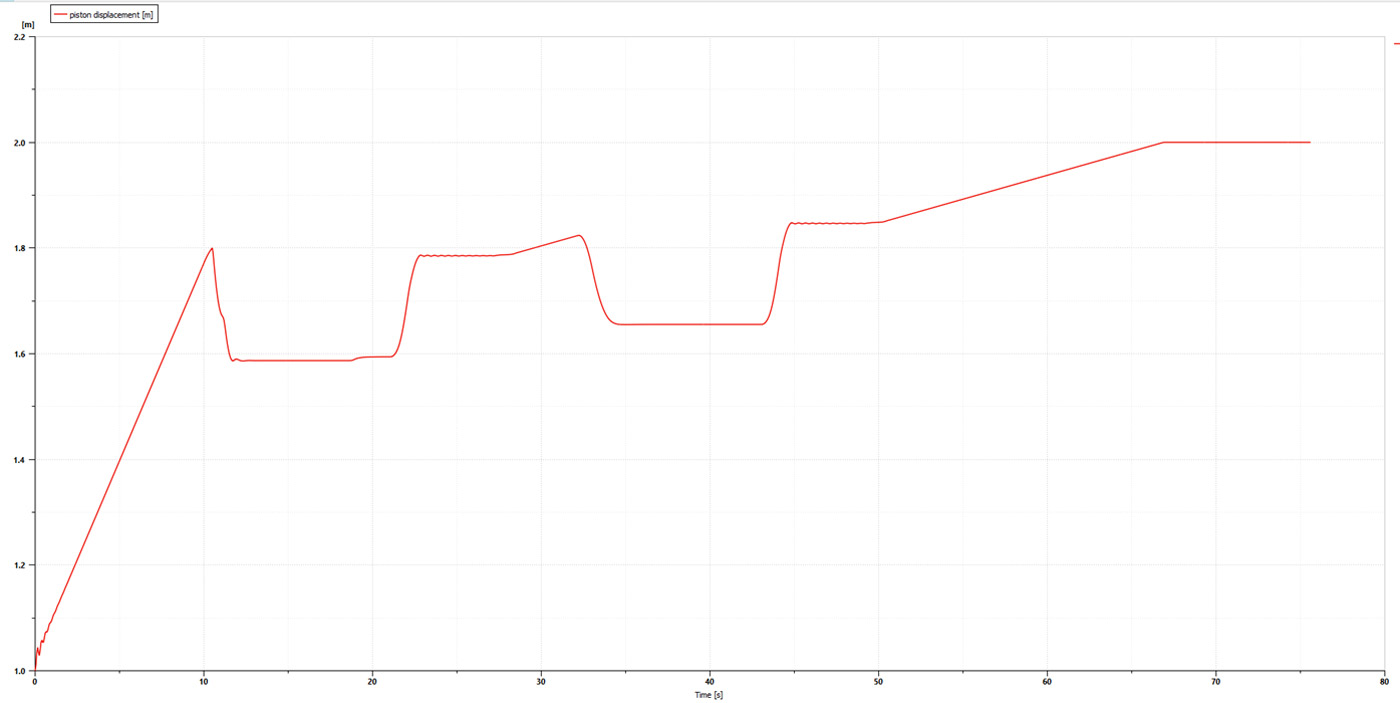

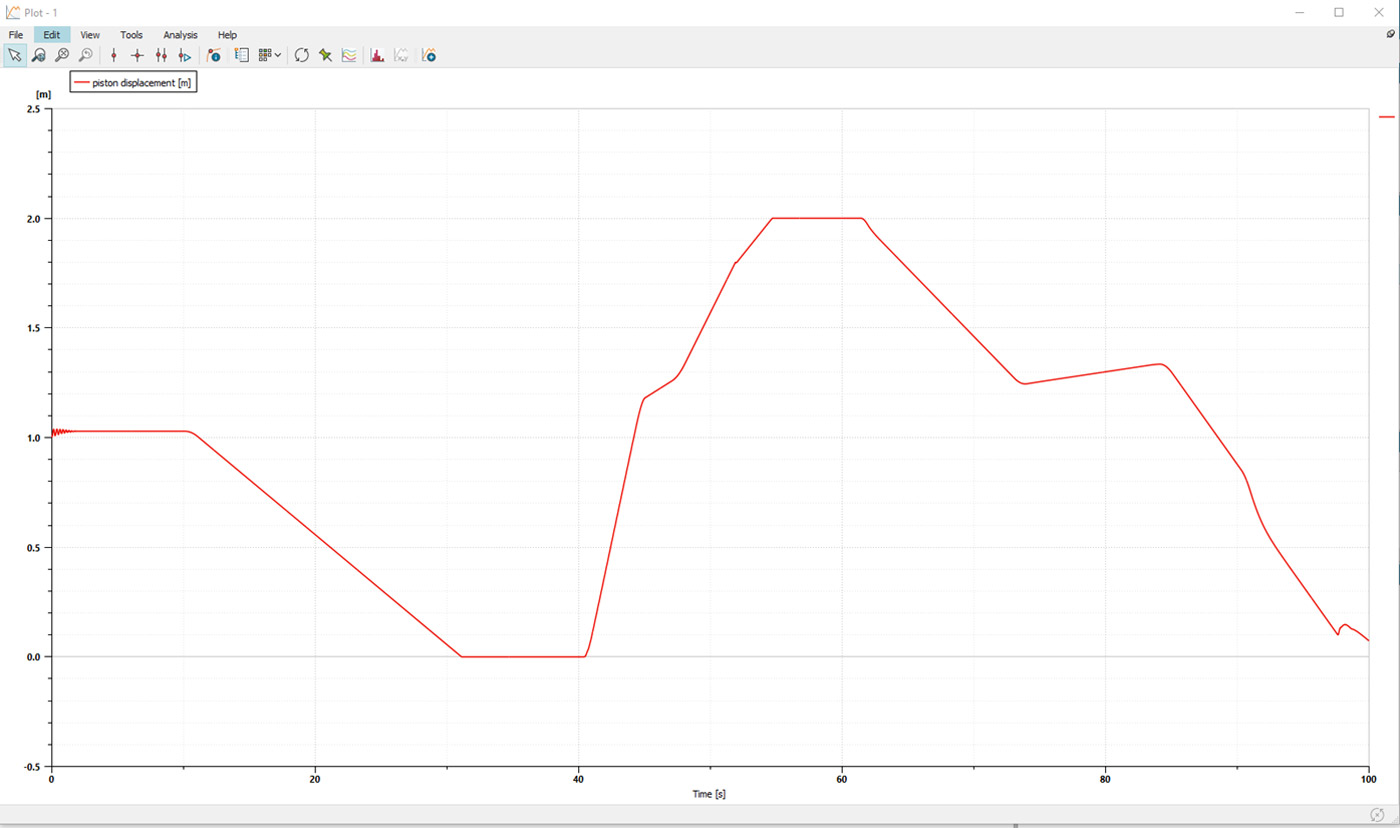

Instead, Advanced Actuators used Simcenter Amesim to understand the circuit's action to produce the required lift and lower of the saw on each stroke. "Part of the contract involved using Simcenter Amesim for an animated demonstration and validation of the proposed system," says Woodhead. "This enabled us to verify the circuit's correct operation before construction."

Through predictive simulation, designers at Advanced Actuators developed a new, less complex hydraulic circuit control system with a more straightforward setup. This reduced the risk of adjustment issues and enhanced the facility's safety. "With Simcenter Amesim, we engineer systems that are quite adept at their tasks without unnecessary complexity," says Woodhead.

Efficiently sustainable

An important secondary benefit of simplifying system complexity is often a reduction in energy consumption. Clients increasingly require performance standards that also lower emissions. Simcenter Amesim enables Advanced Actuators to simulate complete hydraulic systems with pinpoint accuracy. "It means we have more time to concentrate on some of the rest of the nuances and the interaction of components," says Hudson.

This thorough analysis accurately aligns with requirements while validating cost-effectiveness and environmental sustainability. "If we calculate correctly, the energy savings for the customer could last for 20 years or more," says Hudson.

Expanding opportunities

Advanced Actuators' approach to providing a more complete turnkey solution to clients is delivering dividends. "There is a lack of engineers globally," says Woodhead, "and the more we can package this work together and confirm it on Simcenter Amesim, the better."

Advanced Actuators is now channeling the time and cost savings from virtual prototyping into exploring new opportunities. "We are delving into the turbine bypass control market and anti-surge valve controls, which are some very onerous needs regarding position control, accuracy and speed," says Woodhead. "With Simcenter Amesim, we're confident we can meet the customer requirements with greater precision without even producing a physical prototype."